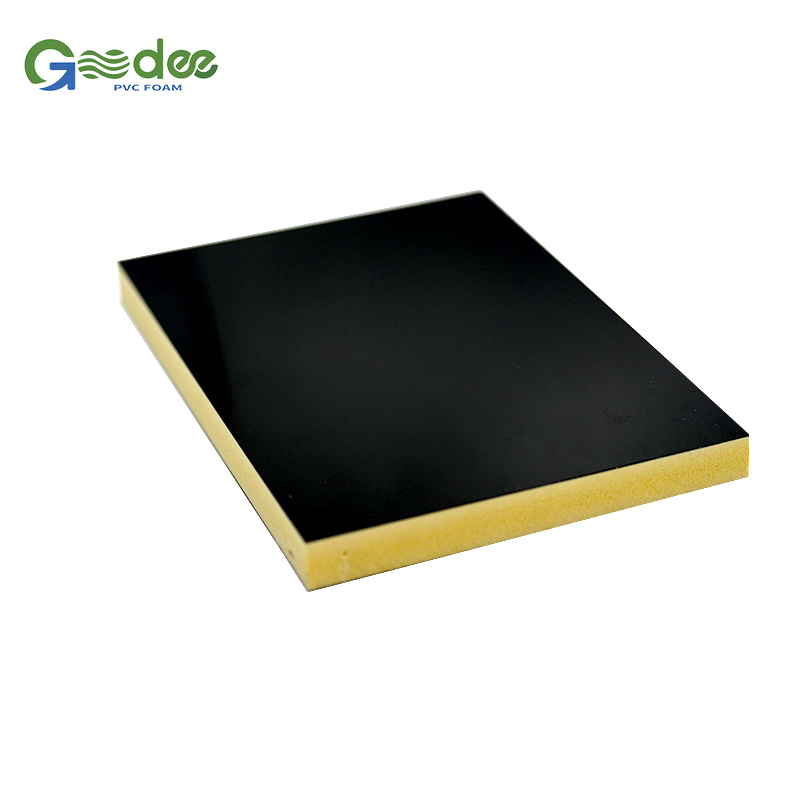

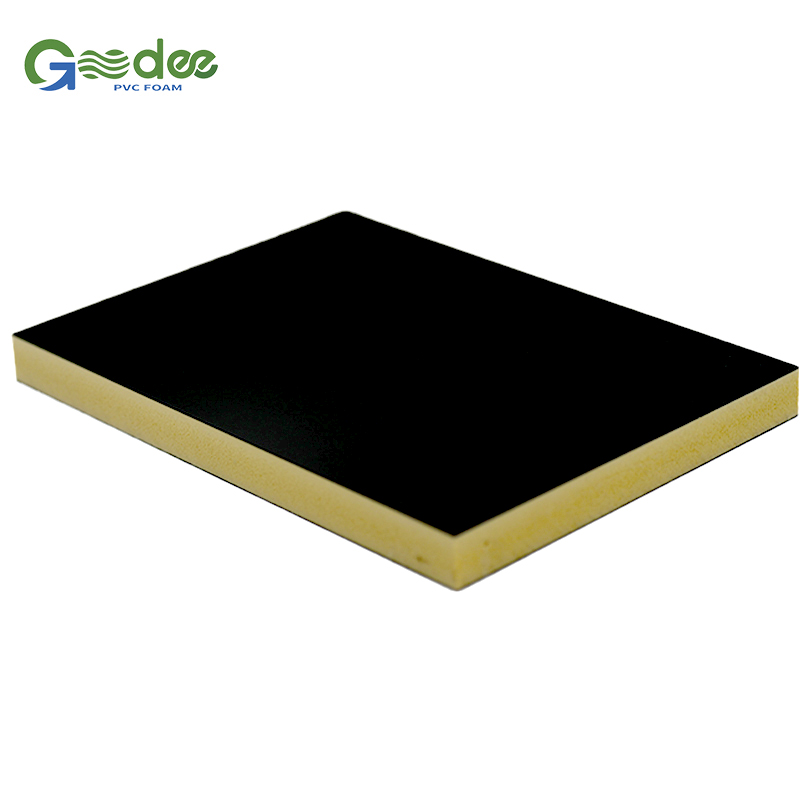

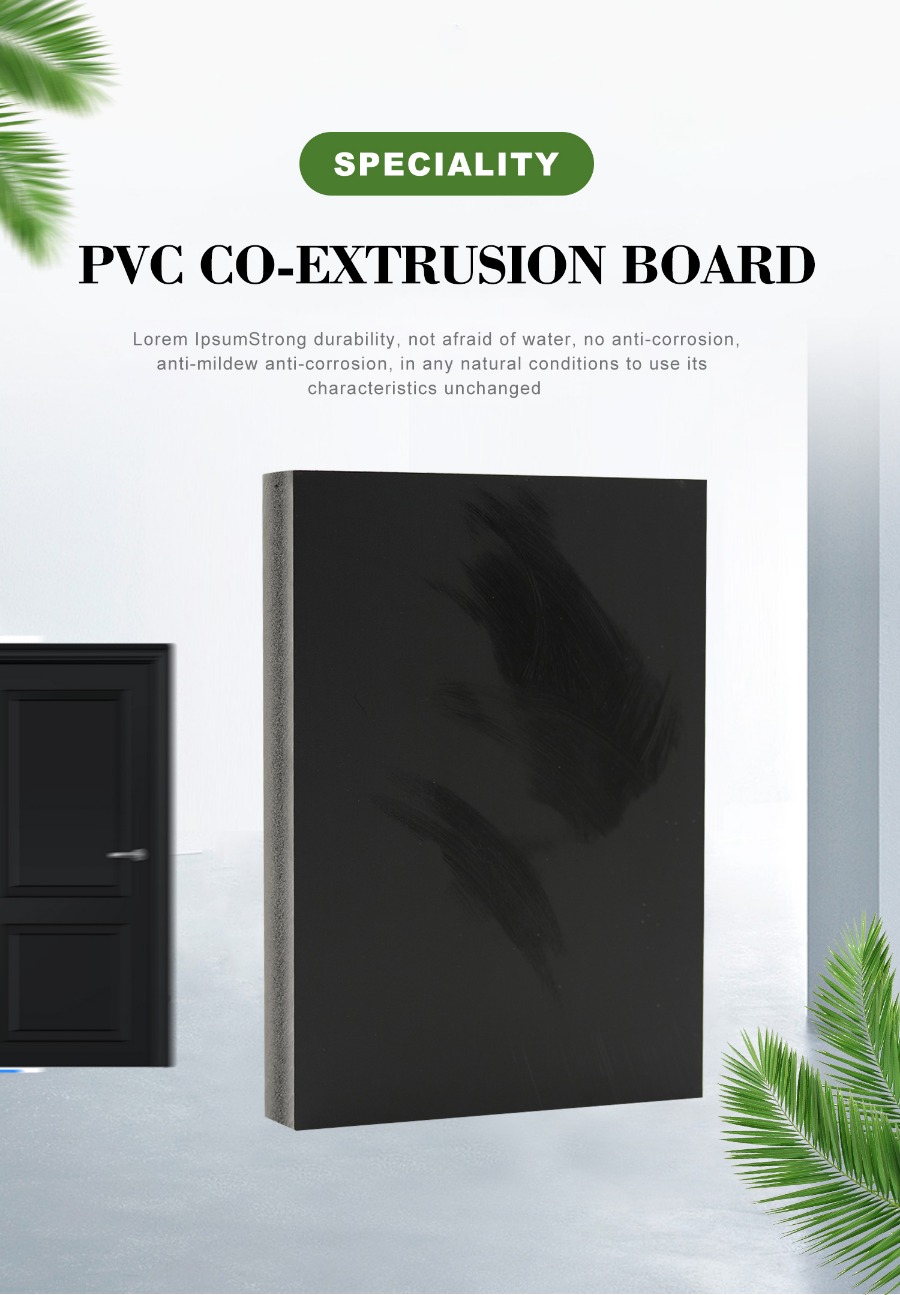

Advantages of PVC co-extruded board(color)

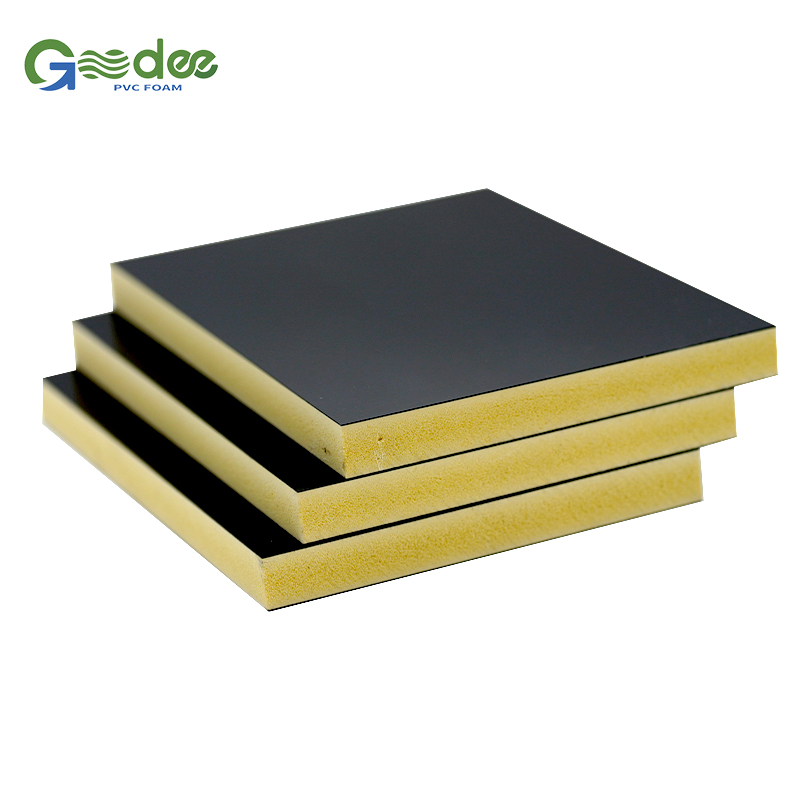

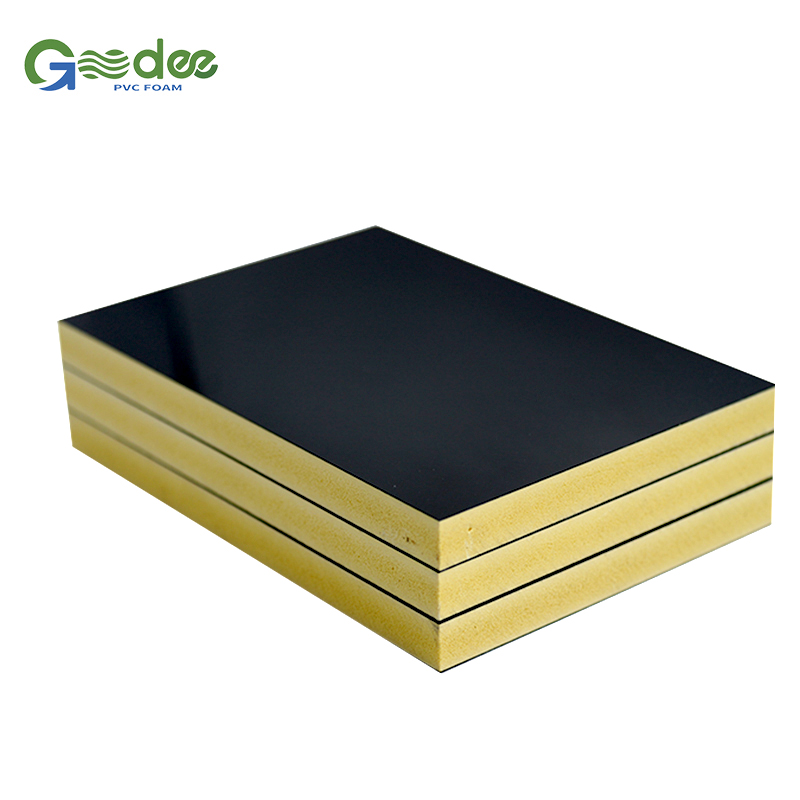

1. High strength and high stiffness: Various materials of the co-extruded plate can be mixed during the extrusion process so that the strength and stiffness of the co-extruded plate can be improved.

2. Corrosion resistance: There are a variety of materials in the co-extruded board, and materials with special properties such as acid resistance and alkali resistance can be selected according to needs, to perform well in corrosion resistance, anti-aging, weather resistance, and other aspects.

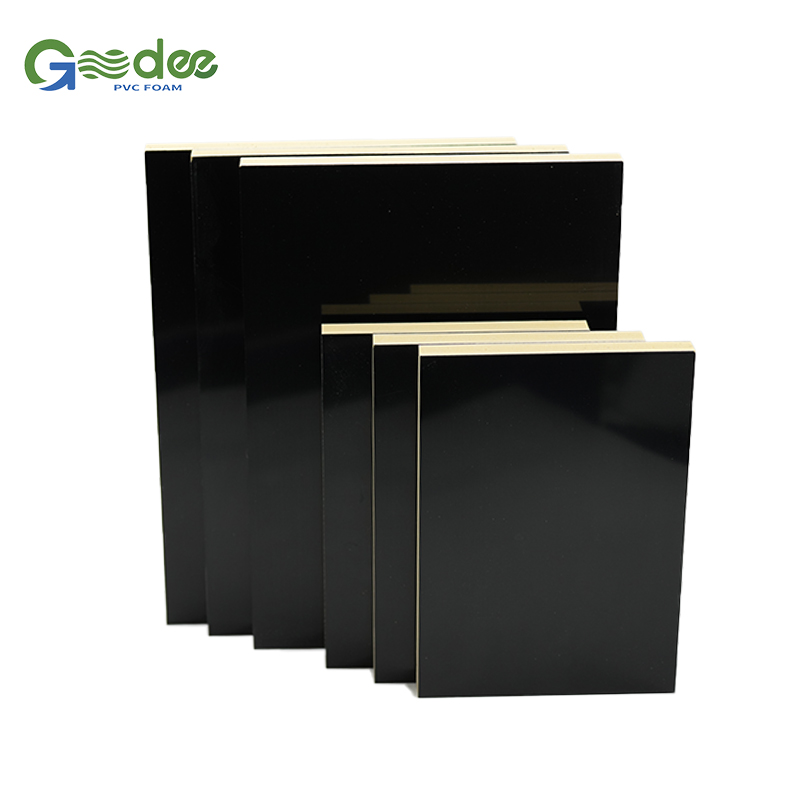

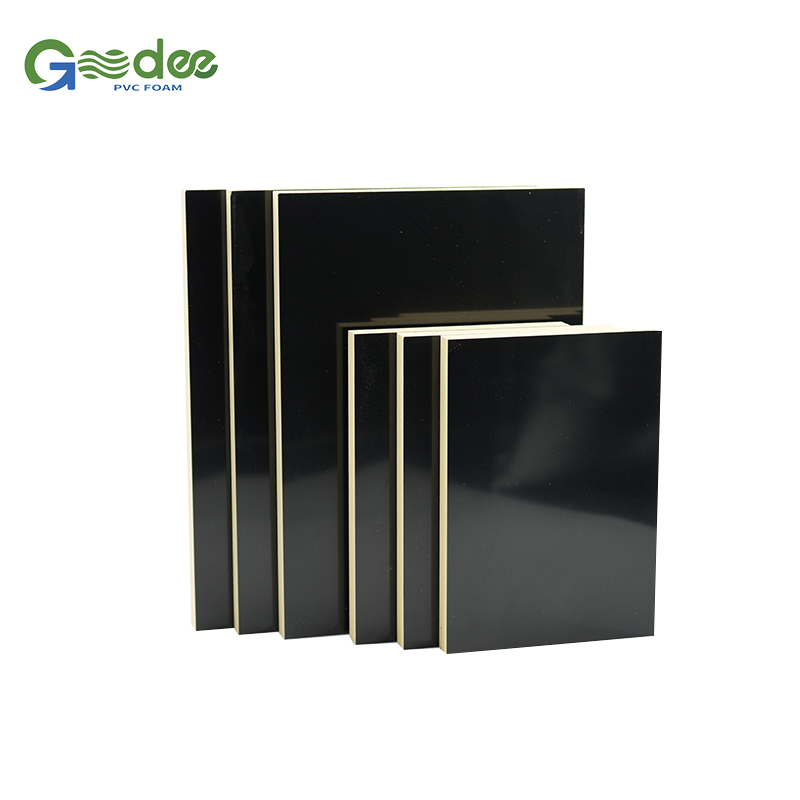

3. Strong flexibility: the co-extruded board can be selected and controlled according to the needs of materials, and can be made into various shapes and specifications of the board, which is very flexible and convenient.

4. Recyclable: Co-extruded board materials can be recycled and used, and the utilization rate of environmental protection resources is high.

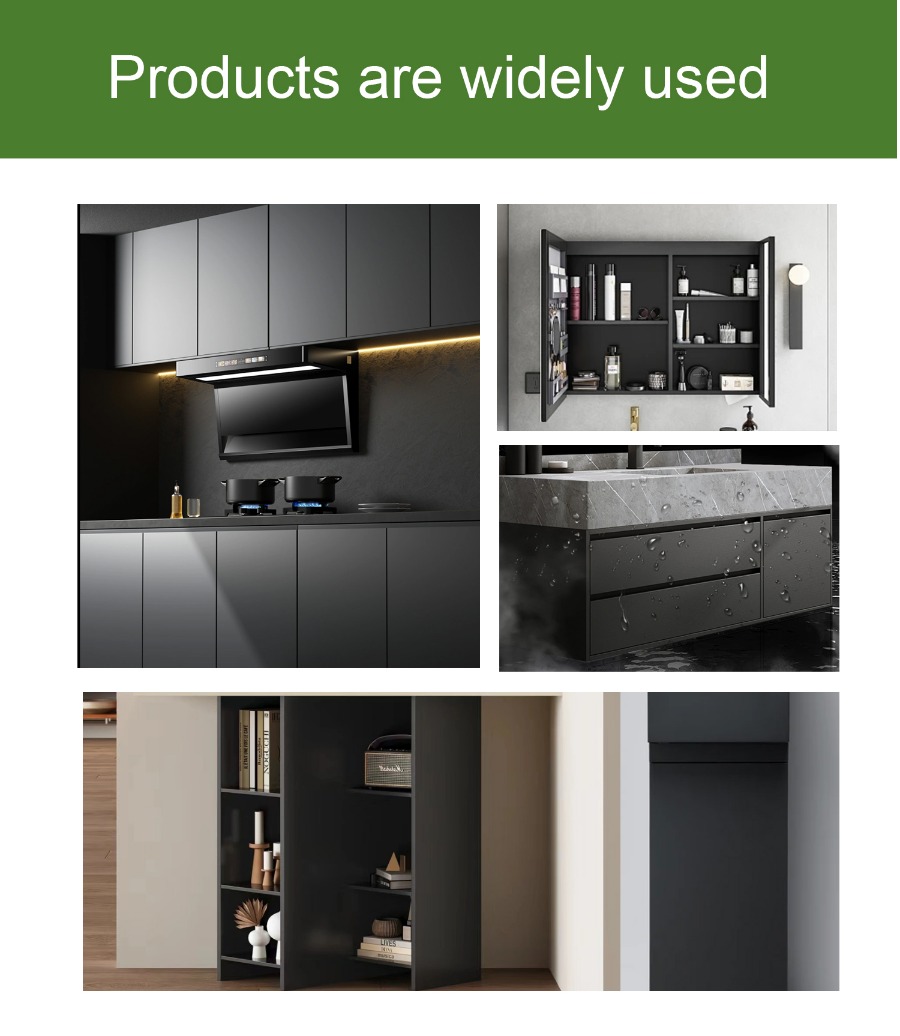

Main application areas of coextruded plates

1. Construction field: Coextruded board is widely used in building interior and exterior decoration, roof waterproofing, heat insulation, door and window manufacturing, and other fields.

2. Transportation field: Co-extruded plates can replace steel and aluminum alloy materials, and are widely used in automobiles, ships, and other fields.

3. Electronic and electrical fields: Coextruded boards can be made into electronic and electrical enclosures or components with heat insulation, moisture-proof, anti-static and other characteristics.

4. Packaging field: The co-extruded plate can be made into various shapes of packaging boxes and plastic cans, bottles, pipes, etc.

In summary, a co-extruded plate is a composite plate produced by extrusion molding technology, which is widely used in construction, transportation, electronic appliances, packaging, and other fields with its high strength, high stiffness, corrosion resistance, and other excellent properties.

English

English Español

Español